Description

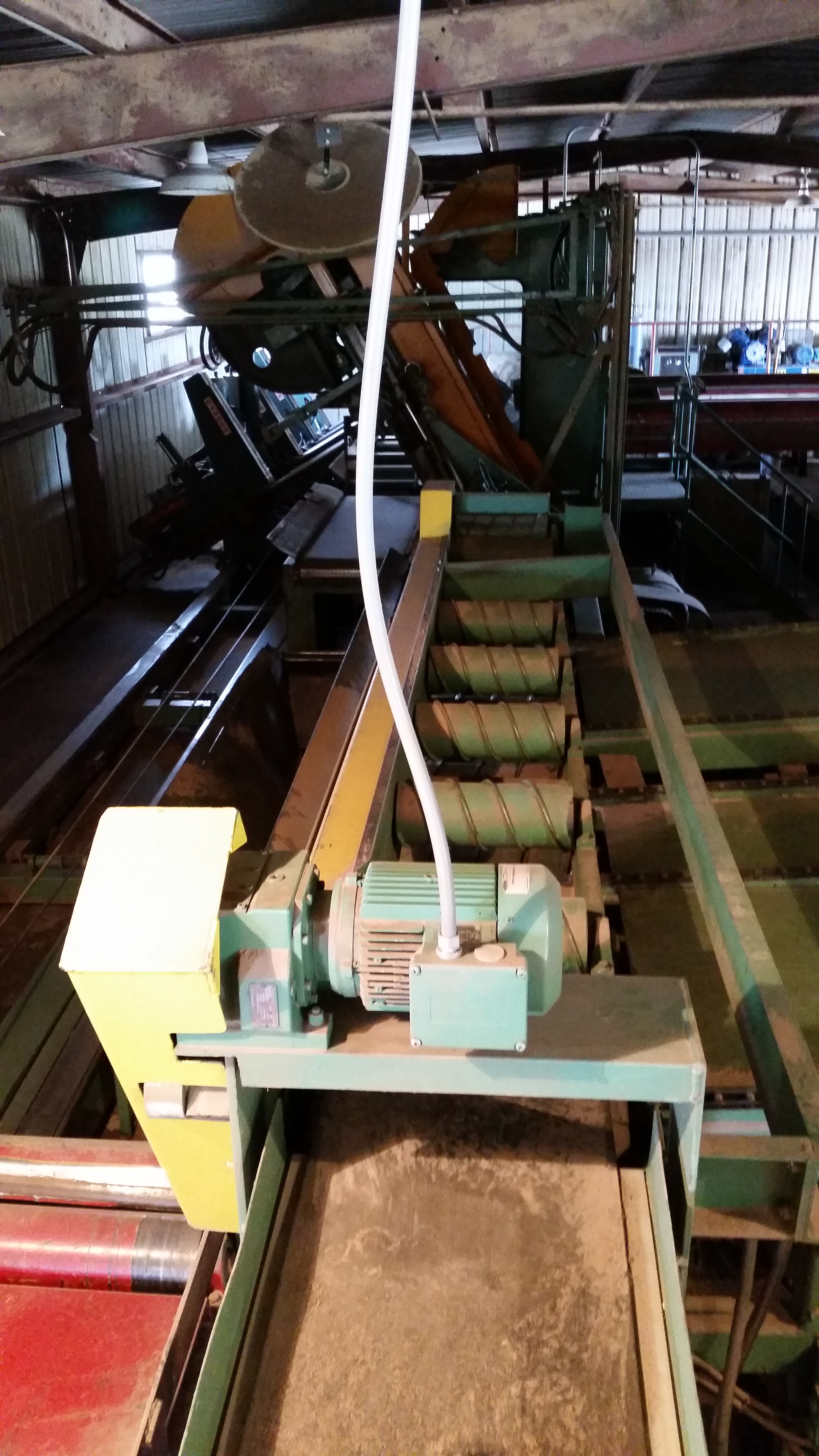

SANBORN 36″ Vertical Resaw system includes the 36” wheel diameter, SANBORN, vertical linebar resaw complete with two hydraulically driven press rolls; 50HP electric motor drive; and hydraulic strain system. The machine runs a 6” wide saw blade and 10 saws are included. There is a cant measuring system included. COMFORTABLY SAWS 14” WIDE x 16” HIGH CANTS.

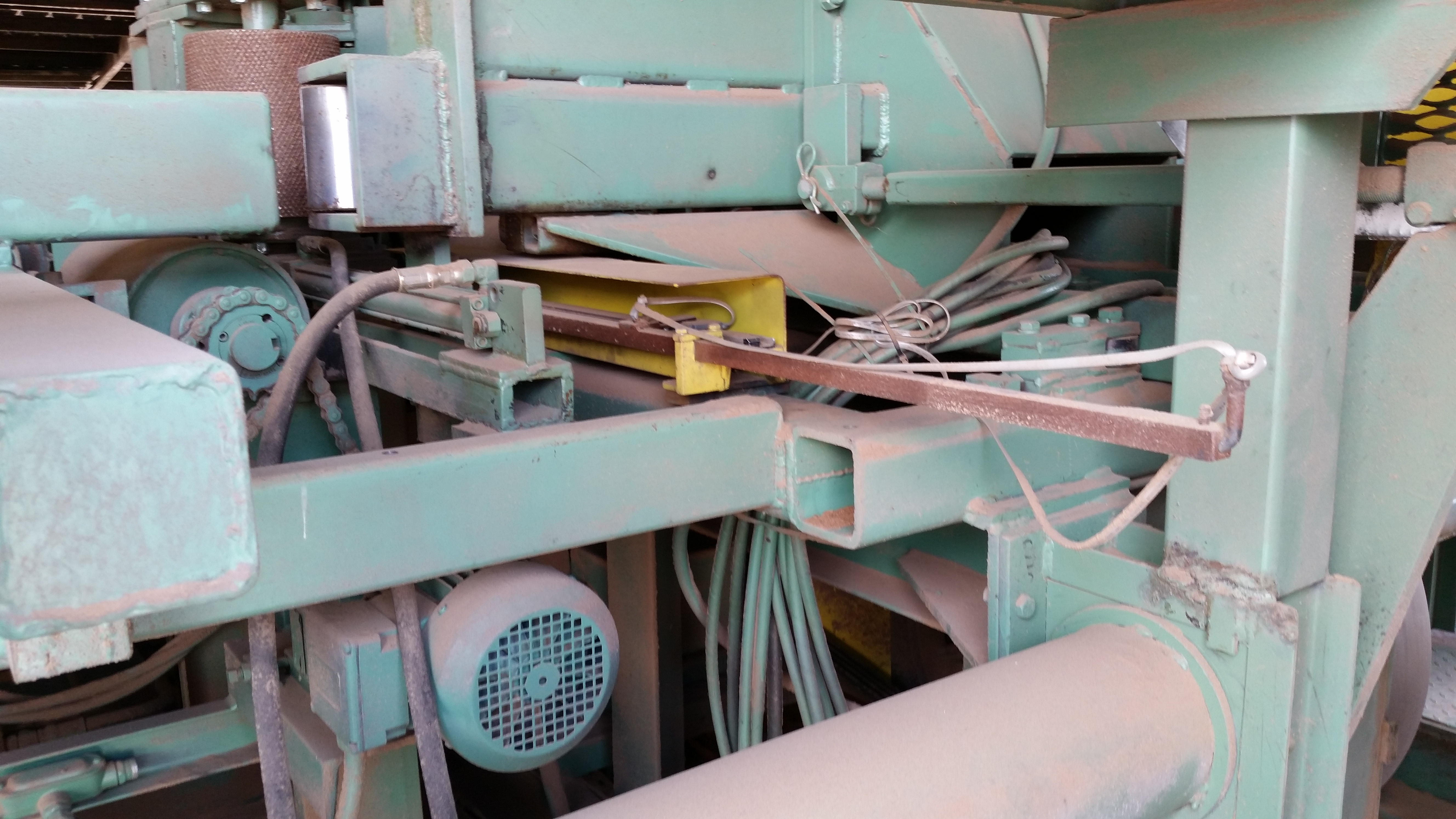

Conveyor system includes all necessary conveyors to:

- The live roll conveyor will receive cants/timbers/boards from a breakdown system. This roll conveyor will feed cants onto the live deck going to the resaw and deliver boards to a collecting chain. Neither the breakdown system nor the collecting chain are included.

- The cants and/or boards feed to the resaw on a 4 strand roof-top collecting chain with holding hooks, which in turn feeds the infeed live roll conveyor.

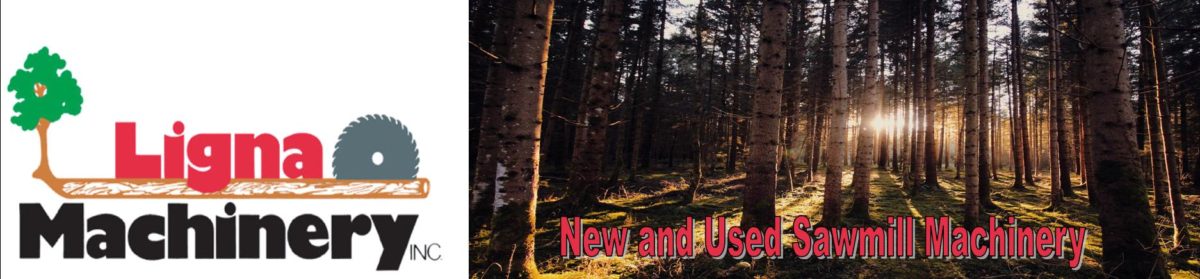

- The live roll infeed has a heavy duty movable line bar system which is moved hydraulically.

- Once the cant exits the resaw, there are a couple of options that the operator has.

- The cant automatically enters into the recycle system which is to your left. The cut board or flitch exits to the right. A splitter plate separates the two.

- Cut boards can: (a) tipple to a collecting chain to feed to an edger conveyor for edging (b) tipple, as a good board without the need to edge, to a collecting chain to be carried to a sorting chain or (c) tipple over the top to fall out of the system. This allows for bad wood or “naily” wood to be removed.

The tipple system, the good board collecting chain, the edger board collecting chain, and the edger belt conveyor are included. The cant recycling live roll conveyor receives the cant from Item 4A. It then feeds the collection chain, mentioned in Item 2.

SYSTEM INCLUDES: OPERATORS CAB WITH CONTROLS; ELECTRICAL SYSTEM WITH STARTER PANEL AND ALL PREWIRED MACHINERY; PRE-PLUMBED HYDRAULIC SYSTEM FOR ALL MACHINERY INCLUDING THE 20HP POWER UNIT; SUBSTRUCTURAL STEEL TO CONCRETE SLAB THAT IT’S SITTING ON; DISASSEMBLY OF MACHINERY READY TO LOAD BUT NO CRANE SERVICES.